Mineral resources are often based on block models of grades within geological domains. The block size is chosen to reflect site specific geological factors and mining selectivity. Subblocks may be used around geological boundaries; however, estimates for the parent block size constitute most of the mineral resource. The estimated grades are often calculated by ordinary kriging using composited drill hole data from the geological domain. The sample assay length is often relatively small to provide high resolution geological information. There may be different vintages of drilling with different sample lengths. Compositing is recommended to get all assay data to a consistent length for the best possible block estimates. Selecting the composite length is an important decision.

The Master’s research of Rose A. Aduko at the Centre for Computational Geostatistics (CCG) provides an in depth analysis of this topic (the optimal composite length for block modeling). This blog provides a summary for practitioners. Jinpyo Kim provides a notebook that allows RMSP users to verify the results and customize with their own deposit parameters.

Some generalizations include: (1) compositing should start and stop at geological contacts, (2) the compositing length should be a multiple of the assay length, (3) very short intervals at the start/end of intersections should be lumped with an adjacent composite, (4) intervals of nearly target length can be kept provided they are not unusually high grade, (5) compositing should be weighted by sample length, (6) compositing should be weighted by density if a reliable model for density exists, and (7) there is no need for compositing to consider the bench elevations. There are specific cases where these generalizations are not applicable.

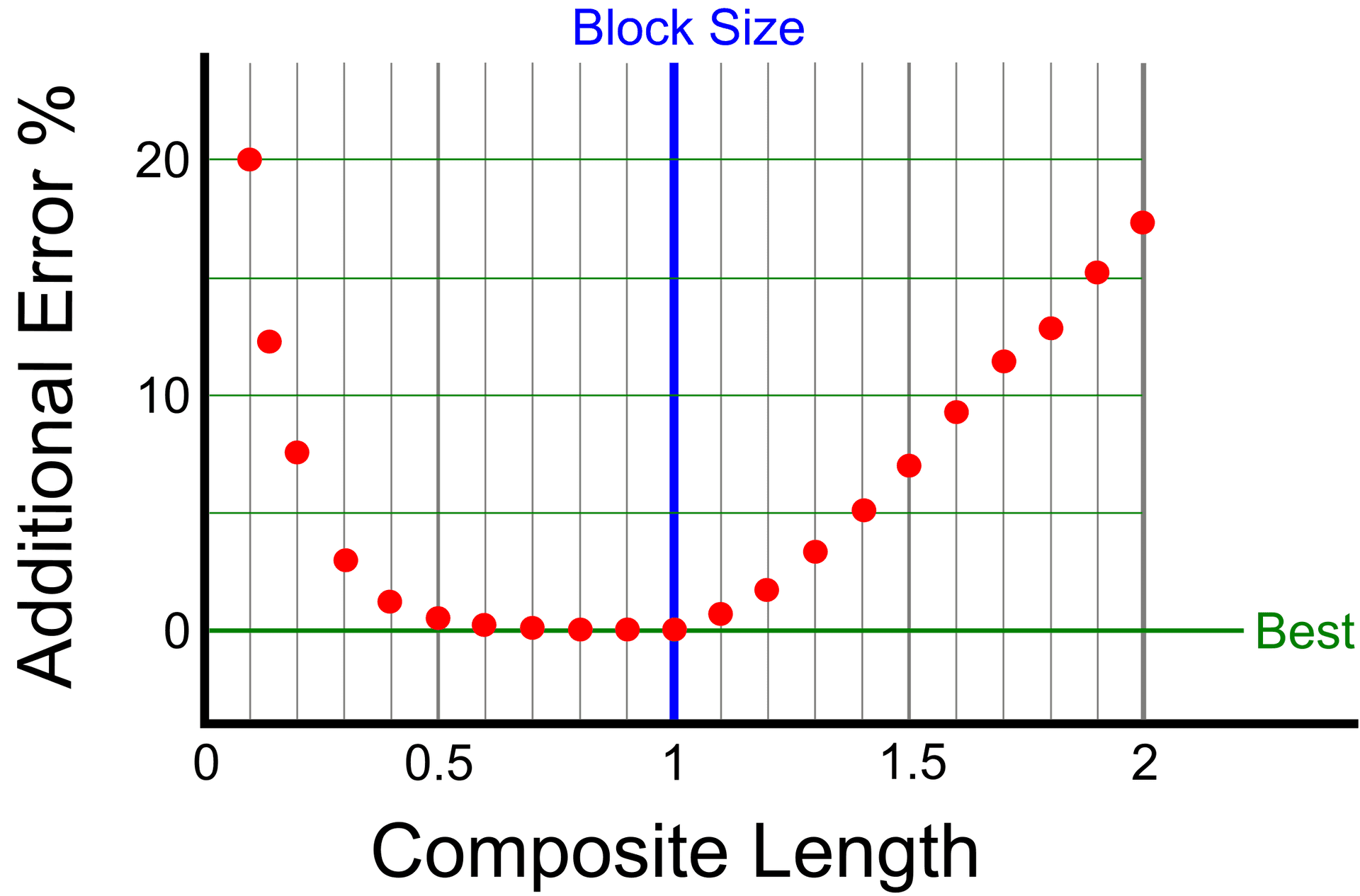

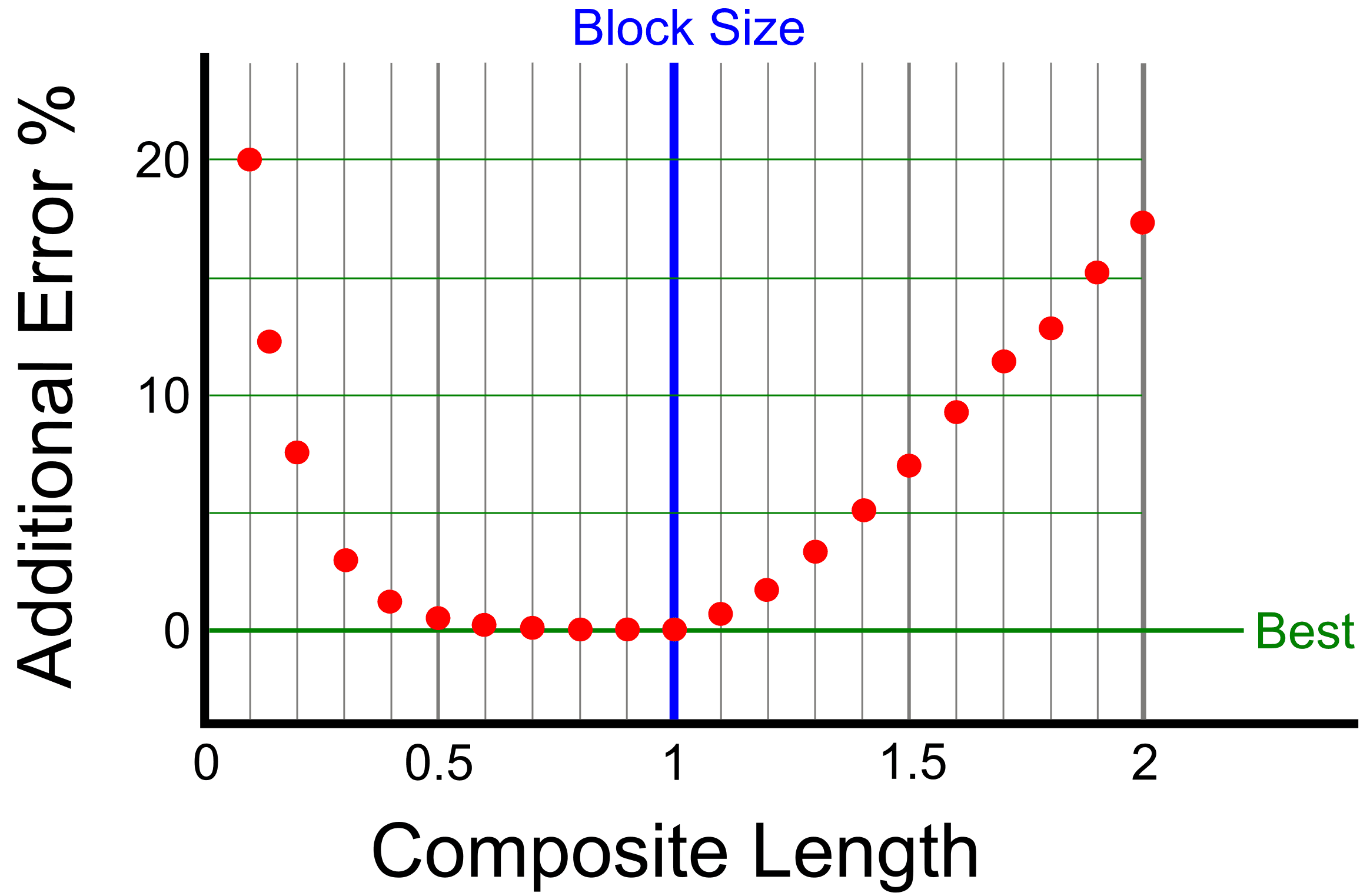

What is the optimal composite length? A too small length would increase the error because of high variability in the values and the string effect whereby more distant edge samples receive large kriging weights. A too large length would increase the error because of smearing the grades and losing resolution at the block size. Many numerical studies have been conducted with true reference high resolution data. The data are drilled at various spacings and composite lengths, then block estimates are calculated. Finally, the error of the block estimates relative to the true block values is computed. The following figure is a generalization of the results. A composite length between 0.5 to 1 times the block size gives the best results.

This generalization is robust with respect to drill hole spacing, variogram shape, anisotropy and many other factors. There are two exceptions to this classic shape. First, when the regionalized variable is completely stationary and a very large number of composites is used for each drill hole and many drill holes are used. In this case, the error for short composite lengths is mitigated, that is, the left side of the curve is flatter and the additional error drops at 0.1 to 0.2 of the block size. Second, when the data spacing is very close relative to the block size, which is unusual since the block size should be about 25% or less than the drill hole spacing; the error for short composites is also mitigated. Although shorter composites may work in these two exceptional cases, a composite length between 50 to 100% of the block size gives optimal results in all cases.

There are some other special cases. Categorical variables are problematic in compositing. Taking majority rules may compromise small proportion categories. Considering proportions may conflict with categorical variable modeling techniques. Non additive variables are also problematic. A bias could be introduced by averaging or compositing. Mixing different data types including drilling with different hole diameter is also problematic. Finally, compositing across the entire thickness of a tabular deposit is a special case where thickness and grade must be modeled appropriately afterwards.

Note that the variogram is sensitive to the composite length. The numerical studies mentioned above consider a different variogram for each composite length. The nugget effect drops quickly as the data are composited. This leads to improved block estimates. Measurement errors are “cancelled out” by the compositing and the variability preserved in the composites is more relevant for the chosen block size.

In summary, setting the composite length at 50 to 100% of the block size and limiting the number of samples per drill hole (to about 3 composites/drill hole) emerges as a pragmatic strategy to enhance the reliability of resource estimates. Simply choosing the most common sample length is unlikely to be optimal. A composite length that is too short introduces noise due to high variability and the string effect, while a composite length that is too long leads to smearing and inaccurate predictions.

Compositing drill hole assay data should be considered for block modeling. Resource Modeling Solutions (RMS) has the latest techniques implemented for optimal and flexible compositing.