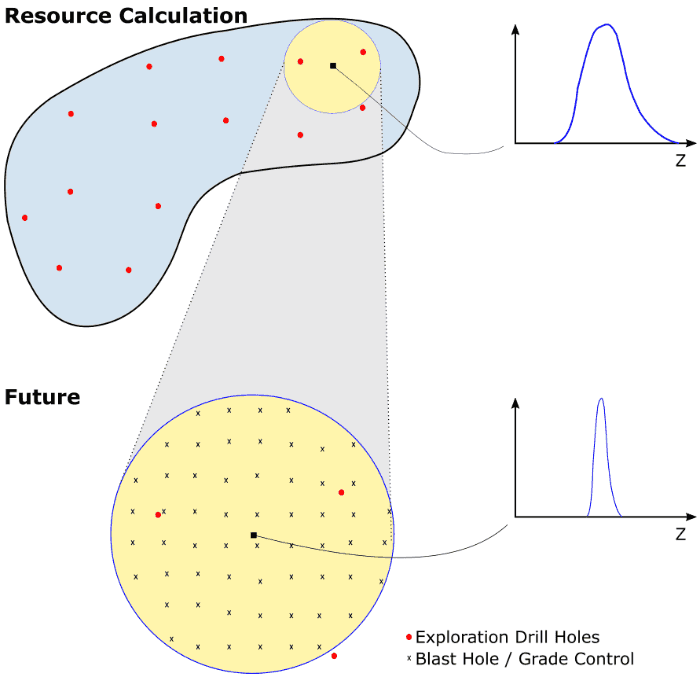

In most cases, mining will benefit from significantly more data in the future than available at the time of resource calculation. There may be one hundred times more data at the time of mining from blast hole samples or dedicated grade control drilling. The uncertainty will be greatly reduced. The best estimate calculated with relatively widely spaced exploration drill holes will not represent what can be achieved at the time of mining. This is referred to as the Information Effect and is managed in different ways: (1) the number of data used in estimation may be reduced to avoid excessive smoothing, (2) a probabilistic model like uniform conditioning could be employed, or (3) simulation and appropriate post processing could be considered. The Resource Modeling Solutions Platform (RMSP) implements all of these options, but what is the best technical approach?

Modifying the smoothing of estimation is practical. Change of support calculations for a chosen selective mining unit (SMU) size provide a target distribution, then the number of data in ordinary kriging is reduced or the exponent in inverse distance is increased to achieve the target distribution. Although practical and simple, this gives conditionally biased estimates with visual artifacts. Although the histogram of the estimates is not overly smooth, the estimates are overly smooth in a spatial sense. This may be a practical approach, but it is not considered the best technical approach.

Probabilistic estimation techniques like uniform conditioning and multiple indicator kriging (with change of support) have seen some application. The probabilistic results can be localized to provide a unique model similar to that coming from estimation. The results depend strongly on stationarity; the change of support coefficients and other parameters are considered stationary in relatively large geological domains. Also, there is no access to large scale uncertainty. Finally, the estimates are overly smooth in a spatial sense. These may be quite fast and convenient, but they are not considered the best technical approach.

A well-crafted simulation workflow where surfaces, boundaries, rock types and multiple grades are simulated accounting for trend models as appropriate addresses concerns with estimation and probabilistic estimation. The simulated realizations can be averaged to selective mining unit volumes representative of future mining. The final realizations could be used directly or they could be localized like probabilistic estimation. Significant computational effort is required, but currently available machines supplemented with cloud computing alleviate this concern. There are other concerns: (1) increased professional time, (2) complexity of the workflow, and (3) more difficult checking and validation. These concerns are addressed by carefully designed modern software. Yes, this is also not considered the best technical approach.

The resource model could be based on a geological model represented at a reasonable block size with some consideration for selectivity and the information effect. The reserve model requires more explicit consideration of the information effect.

The problem with all of these approaches is that they rely on the concept of an SMU block size. The SMU indirectly accounts for future mining selectivity, blast movement, grade control sampling, visual control and myriad geological and operational considerations. There is no direct link to any of these important factors. Also, the concept of an SMU may be reasonable in open pit surface mining, but it is not applicable in most underground mine settings. Mineable stopes are very different than open pit mine faces. The correct methodology to account for mining selectivity and the information effect is clear. The concept of simulation is extended. In addition to simulating the geology and grades, the acquisition of future information, short-term planning and mining extraction can also be simulated. This has been implemented and the results reconciled with production. This is the best technical approach in my opinion.

There are many calculation and methodological details that are beyond the scope of this blog – they are found in example case studies and in documentation; however, consider that each realization of the deposit is carried further down the calculation chain. Each realization is sampled at the anticipated production sample spacing, reasonable errors are added to the simulated data, the short term mine planning is implemented and the reserve is assessed with the true underlying realization and the simulated extraction plan. For open pit, the short-term model would include modeling with all data, simulating blast movement and applying reasonable dig limits. For underground, the short-term model would include modeling with all data, stope planning, and a model for the deviation from as-planned. The results are sensitive to the details of future mining, but that is correct.

Resource Modeling Solutions focuses on workflows and a software platform for resource and reserve calculation with the best technical approaches and rational validated assessments of uncertainty.